Qingdao Nansha Taixing Technology Co., Ltd., founded in September 2005, has been dedicated to the research, development, production and application of new carbon materials for many years. It operates with ingenuity and innovation. Now it has 26 invention patents and utility model patents. In 2014, the company became the first “national high-tech enterprise” in the graphite industry of the city. The company always adheres to the foundation of scientific and technological innovation, the business approach of excellent quality, and the enterprise spirit of people-oriented and social dedication.

The company has successively passed ISO9001 quality management system certification, ISO14001 environmental management system certification, safety and environmental protection double system acceptance, issued and implemented the industry’s highest product standard for ultra-thin graphite heat dissipation film [TS001-2018], and successively registered two trademarks, “Nansha” and “Nansha Taixing”. The market recognition of the products has been gradually improved, and participated in the formulation of the industry group standard for graphene heat dissipation film, In 2018, it won the Shandong Province Circular Economy Science and Technology Achievement Award.

In 2011, the company cooperated with Harbin University of Technology (Weihai) to successfully develop a high thermal conductivity ultra-thin heat dissipation film. The successful research and development of this project has filled the domestic gap, won the innovation fund of the Ministry of Science and Technology of the People’s Republic of China, and has been included in the Qingdao emerging strategic new material support project. At present, the company has two ultra-thin heat dissipation film production lines, with an annual production capacity of 1 million square meters. The research and development of this project has well solved the thermal management problem of electronic products and can be widely used in mobile phones, tablets, televisions, LEDs and other communication devices.

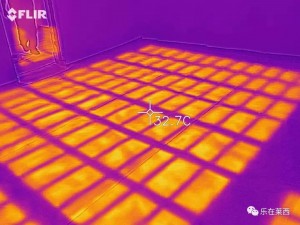

Since 2015, in line with the national policy of “replacing coal with electricity” and the people’s pursuit of a healthy life, the company has invested more than 3.1 million yuan in cooperation with Harbin University of Technology (Weihai) and the School of Materials of Zhejiang University to research and develop graphene electrothermal film and its various application products. After three years of unremitting efforts, at the end of 2017, it successfully broke through the graphene inorganic composite electrothermal film and graphene PTC (self limiting temperature) electrothermal film technology. The graphene inorganic composite electric heating film can be widely used in various electric heaters, industrial heating appliances, etc. The successful development of this technology has solved the problems of pollution in the production process of the original metal heating film (wire) and oxidation attenuation in the application process. The graphene inorganic composite electrothermal film has been tested by the National Infrared Electrothermal Testing Center, and the electrothermal conversion rate is more than 98%. It has zero attenuation under the service environment of 400 ℃, and its service life is unlimited. The graphene PTC (self limiting) electric heating film has solved the hidden danger of high temperature safety after covering the constant power electric heating film that has puzzled the industry for many years. According to the national infrared detection center, the electrothermal conversion rate is 98%, 30000 hours of micro attenuation, the far-infrared full normal emissivity is 88%, and the infrared electrothermal conversion rate is 68%. It is widely used in residential heating, far-infrared health physiotherapy, animal and plant greenhouse heating and other fields. PTC (self limiting temperature) technology is a technological revolution of electric heating film. Our company’s PTC (self limiting temperature) technology once again fills the technical gap in the industry and is at the leading domestic and international level.

In 2018, the company has successively invested more than 5 million yuan to develop and improve the production process technology, jointly developed and put into production an automatic production line for die-cutting and automatic cutting of graphene inorganic composite electric heating film with relevant automation equipment manufacturers, making the process production of graphene inorganic composite electric heating film achieve standard automatic production, with an annual production capacity of 3 million square meters. A production process of graphene PTC slurry, an automatic PTC printing production process, and a series of related supporting process equipment have been developed and put into production. The production has begun to take shape. The annual production capacity of PTC electric heating film can reach 1.5 million square meters, which can initially meet the market demand. The company will continue to increase investment and expand production scale to meet the growing market demand.

With the improvement of electrothermal film technology and process, two series of electrothermal products have been successively developed. First, heating products for residents: there is a low-temperature radiant floor heating packaging film suitable for laying on different floors. This electric heating film solves the problem of induced current very well. The floor heating film has low cost for laying, simple construction, fast heating speed, and the initial working hours can reach 18 ℃, which is a one-time investment and permanent benefit; There are integrated heating wallboards and kang boards suitable for office space and rural “coal to electricity” project. The integrated wallboards have large heat dissipation area and fast construction, which can solve the heating problem of the houses that have been decorated and are in use. The integrated kang board is the best choice for coal to electricity in rural areas. The use of 24V DC power supply is safe, reliable, healthy and comfortable; There is an electric heater suitable for different places, which can be used when it is powered on. The independent heating chip is adopted, and the air duct is self circulating, with no noise and high energy efficiency. Compared with the traditional electric heater, it can save about 30% of electricity; It has an integrated roof heating and top hanging design that is suitable for workshop work position and home toilet, which is safe and energy-saving, does not occupy space, does not pollute, and is easy to use; There are also convenient heating murals with obvious decorative effects. This series of graphene electric heating products can be remotely controlled by intelligent mobile phone APP, which is safe, intelligent and convenient, and can be used to control the temperature anytime and anywhere. Second, a series of health products. After the graphene heating film is powered on, its far-infrared full normal emissivity is as high as 88%, which is consistent with the “life light wave” (9~16 microns) in the sun. When it penetrates into the human body, it can cause the molecular resonance of human cells, effectively promote blood circulation, improve metabolism, enhance the regeneration function of cellular tissues, improve the immunity of the body, so as to play a health role. At present, a series of wearable products have been launched, such as knee protection, waist protection The palace, neck, shawl, vest, etc. have very good health care effect on lumbar muscle strain, cervical pain, arthritis, uterine cold and other symptoms. It also introduced a graphene “sun bed”, which uses 3D environment-friendly materials and an “X” hollow three-dimensional structure to perfectly fit the human body curve. It is hard but not stiff, soft but not collapsed, breathable and heat dissipating, moisture-proof and mildew resistant. It plays an incomparable auxiliary role in the field of professional nursing for the elderly and postpartum recovery nursing. With the continuous improvement of people’s living standards and the constant pursuit of healthy life, Taixing Technology will develop more and better graphene far infrared health products that meet the needs.

Graphene far-infrared physiotherapy protector

The product is aimed at the five parts of the human body that are most prone to pain

Sunshine bed – let you feel the warmth of the sun while sleeping

Graphene electric heating series products

Post time: Apr-28-2020